Ultrasonic Cutting Machines

1) Advanced PLC controller with 7" colour touch screen. Servo based fabric feeder with smooth high speed operation with greater productivity.

2) Mechanical Conversion Flexibility: We have provided all the cutouts and holes in our machines to insert any type of cutting system.(HOT, Cold or Ultrasonic cutting type). So We can convert our machines of one type cutting to other type of cutting in one day in customer place only. No need to send Vendors shop floor. i.e,

- We can add Cold Cutting setup to any of our HOT cutting or Ultrasonic cutting machines in one day without sending machine to any vendor's shop floor.

- We can convert any of our machine from HOT cut to Ultrasonic Cut machine in One day at your place only.

- We can convert any of our machine from Ultrasonic cut to HOT Cut machine in One day at your place only.

- We can add Edge folding and Ultrasonic Sealing in any of our machines in one day only.

3) Automatic speed synchronization between feeder servo and unwinder motor, so that no need to change the unwinder VFD speed every time even at higher size cut-length up to 30 meter. The speed of servo and unwinder will automatically adjust for best matching maximum speed.

4) Servo operated Auto Spout Movement: We have introduced this feature first time in the Market. The spout will automatically adjust according to your cut length entered in HMI.

Which will save your Fabric Wastage and Setting time too.

5) Remote Monitoring & Control: Remote monitoring and controlling of HMI screen is possible within LAN via PC, Laptop or Android mobile.

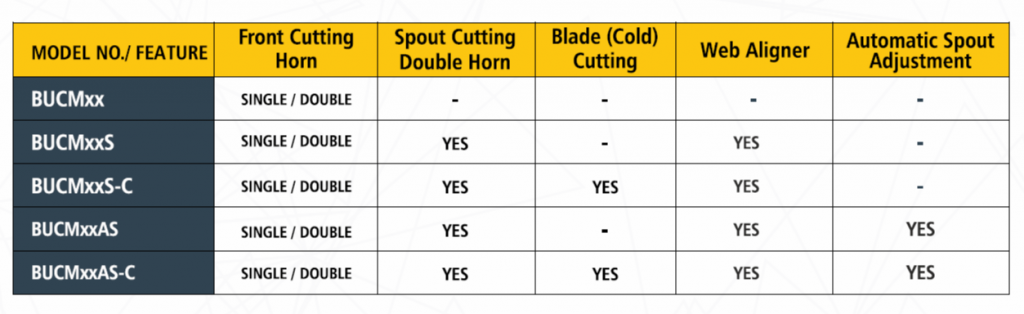

Model Features